Clock¶

The clock produces signals that synchronise the operation of all the other modules in the computer.

It can drive the operation of the computer step by step for debugging or at an arbitrary speed.

Interface and Operation¶

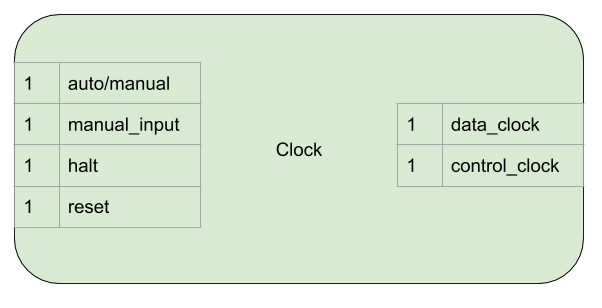

This is the interface to the clock:

And this is how it operates:

| Name | Bit width | Description |

|---|---|---|

| auto/manual | 1 | When low, the clock signals are advanced manually with manual_input. When high, clock signals are advanced automatically. |

| manual_clock_input | 1 | High/low transitions here will advance the clock signals. |

| halt | 1 | While high, bring both of the clock signals low and stop them advancing. |

| reset | 1 | While high, bring both of the clock signals low and stop them advancing. |

| data_clock | 1 | Alternates between high and low, driving the data transitions in the computer. |

| control_clock | 1 | Alternates between high and low, driving the control signal transitions in the computer. |

Control and Data Clocks¶

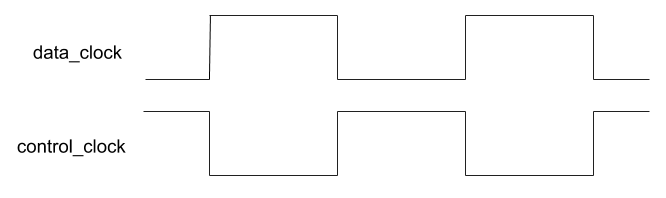

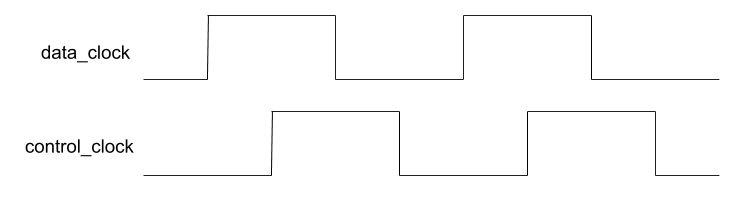

Typically the clocks in other computers invert data_clock to create control_clock, like this:

This is not suitable for this computer due to some restrictions on the 74HCT161 used in the Program Counter. Here is the note from the datasheet:

Note

- The High-to-Low transition of PE or TE on the ’HC/HCT161 and the ’HC/HCT163 should only occur while CP is HIGH for conventional operation.

- The Low-to-High transition of SPE on the ’HC/HCT161 and SPE or MR on the ’HC/HCT163 should only occur while CP is HIGH for conventional operation.

This means:

- PE going from high to low (i.e. disabling counting) must happen while data_clock is high.

- SPE going from low to high (i.e. disabling parallel load mode) must happen while data_clock is high.

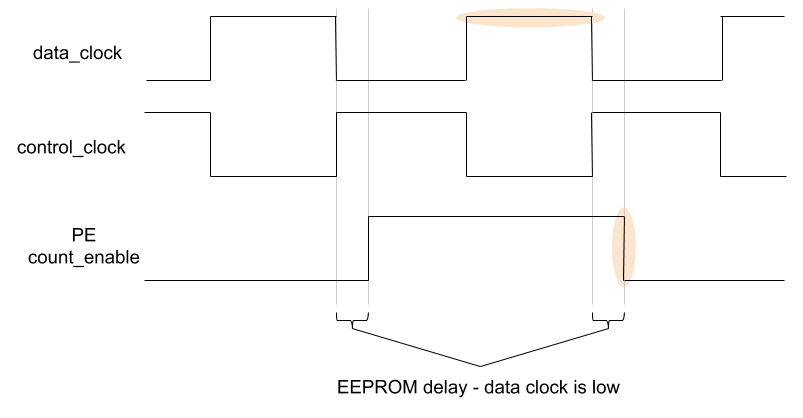

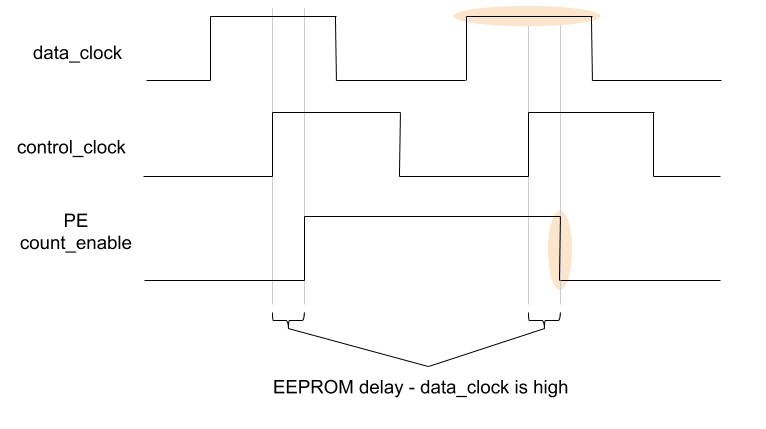

The inverted clock method doesn’t satisfy this constraint as control signal changes (which happen a short delay after the rising edge of control_clock) would occur after data_clock had gone low. The delay is introduced by the EEPROMs in the Control Unit settling after a new instruction/flag/micro-step value goes onto their address lines. This demonstrates the problem using the PE control (_SPE is the same):

To satisfy this constraint, the two clock signals proceed like this:

This means data_clock is still high when PE/count_enable changes:

Halt and reset¶

Once halt or reset go high, both data_clock and control_clock immediately go low. Once halt and reset go low again after either becomes high, data_clock should be the first to go high and the then sequence continues. This is to ensure correct timing gaps are left when operation of the computer resumes.

Implementation¶

Even duty cycle¶

The 555 astable circuit used does not always output a signal with an even duty cycle. To fix this, the output from the 555 is fed into the clock of a JK flip flop configured to toggle. This halves the frequency of the astable output but guarantees it’s at a 50% duty cycle.

Block diagram¶

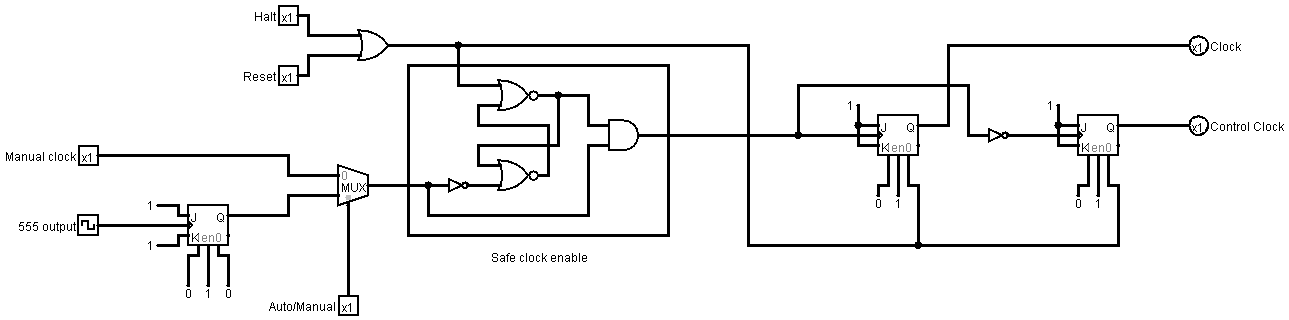

Logically the clock is implemented as follows:

From left to right:

- Manual and 555 clock signals.

- Feed the 555 into a JK flip flop configured to toggle to achieve even duty cycle.

- Multiplex to choose the manual or auto clock.

- Halt and reset signals - effectively do the same thing - stop the clock.

- Safe Clock Enable. This ensures correct timing of the clock after reset is released.

- Two JK flip flops configured to toggle, one fed with the inverse of the gated clock signal to be the delayed signal for the control clock.

However, in reality the layout is equivalent, but a little more complex due to implementation details in the other chips (active low inputs) and trying to make the best use of space and gates available on chips:

Hardware¶

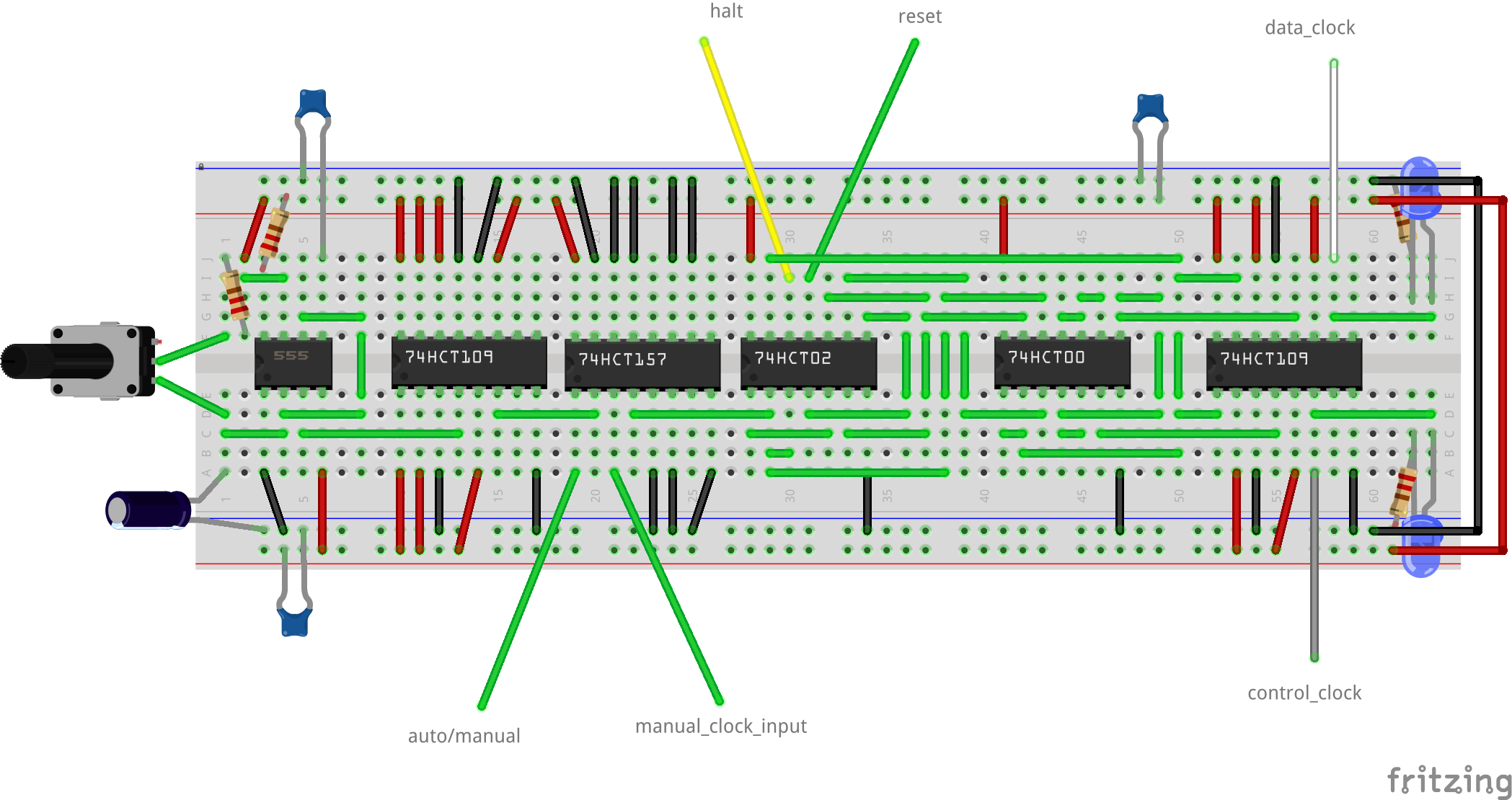

The following electronics are used:

- A 555 and accompanying resistors and capacitors to generate the auto clock signal.

- A 74HCT109 to get an even duty cycle from the 555.

- A 74HCT157 to multiplex between the manual and auto clock signals.

- A 74HCT02 and 74HCT00 to create the safe clock gate and some additional signal inverting.

- Another 74HCT109 to provide the last 2 toggles for the clocks.

The components are laid out on the breadboard like so: